A fixture is a work holding or support device used in the manufacturing industry. Fixtures are used to securely locate (position in a specific location or orientation) and support the work, ensuring that all parts produced using the fixture will maintain conformity and inter-changeability.

Machining Centre Fixtures

Forms and Gears designs and manufactures machining centre fixtures for customers all over the world. Machine makers and Automobile makers from various parts of the world source their fixtures from Forms and Gears. These hydraulic fixtures unlock the full potential of the machining centres by dramatically increasing machining speeds and reducing operator dependence.

Advantages of High-Pressure Hydraulic Power Fixtures:

- Quicker Clamping

- Quicker Machining

- Improved Component Quality

- Consistent and Repeatable Operation

- Controlled Clamping Force

- Automatically Adjusting Work Supports

Other Benefits:

- Remote Clamp Operation

- Reduced Operator Fatigue

- Automatic Sequencing

- Fixture Compactness

- Increased Machine Capacity

Assembly Fixtures

Forms & Gears has developed a large number of assembly fixtures for clients like Hyundai, Ford, Renault Nissan, Alstom etc.

A large quantity of Engine Decking fixtures have been developed for the automakers. Engine decking fixtures are used to mount the engine assembly which comes from the engine shop onto the automobile in the assembly shop.

Engine test cells and Test Rigs

Engine Test rigs and Test cells are used to reduce set up time inside the engine testing facilities while the engines are docked onto the dynamometer while various parameters are tested. This consists of a mother unit that is permanently mounted inside the engine testing cell and multiple test carts on which individual engine assemblies are located and mounted.

Each test cart is brought into the engine testing facility and this is located and hydraulically clamped onto the mother unit and the engine docked onto the dynamometer. All inputs into the engine like oil, gas, fuel etc are mounted on a quick coupling manifold which docks onto a receiving manifold on the test cart.

Hydraulic Powerpacks

Hydraulic Powerpacks are stand-alone devices, as opposed to a built-in power supply for hydraulic machinery. A hydraulic system employs enclosed fluid to transfer energy from one source to another, and subsequently create rotary motion, linear motion, or force.

They have a hydraulic reservoir, which houses the fluid, regulators that allow users to control the amount of pressure the power pack delivers to a valve, pressure supply lines and relief lines, a pump and a motor to power the pump. The mechanical characteristics and specifications of a hydraulic power pack dictate the type of applications for which it can be effective.

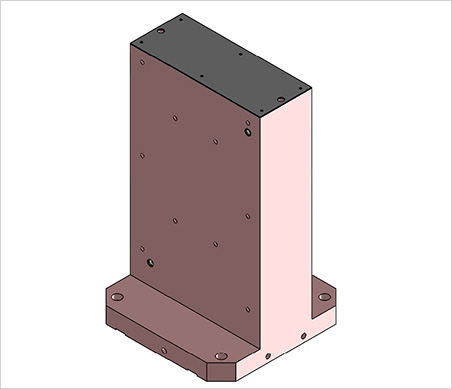

Tombstones

A tombstone, also known as a pedestal-type fixture is a fixture of two or more sides, onto which are mounted parts to be manufactured. Typically, fixtures are activated by pneumatics or hydraulics.

Weld Jigs

Welding Jig is a large brace that keeps a welding project stable in the face of pressure, heat, motion, and force. A quality jig will streamline welding work by keeping parts together in a vice grip, whether the welding is entirely manual, partially automatic, or fully robotic.